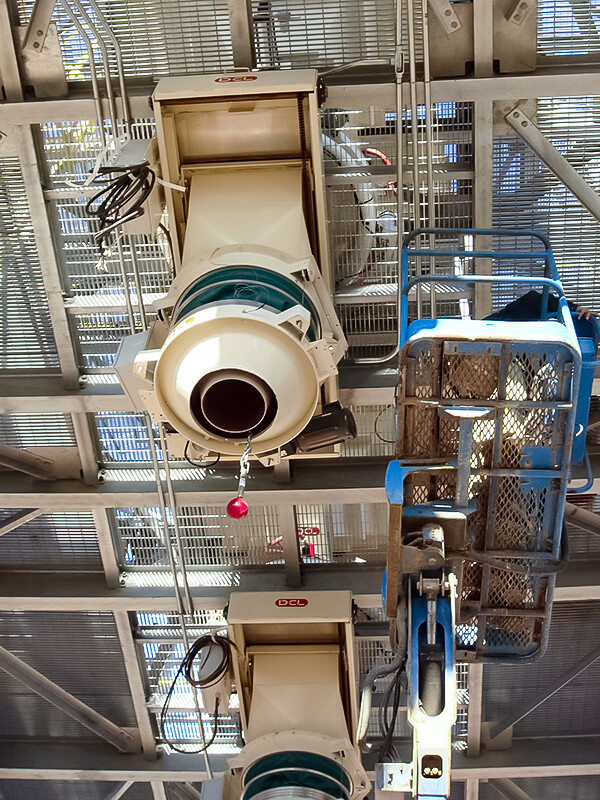

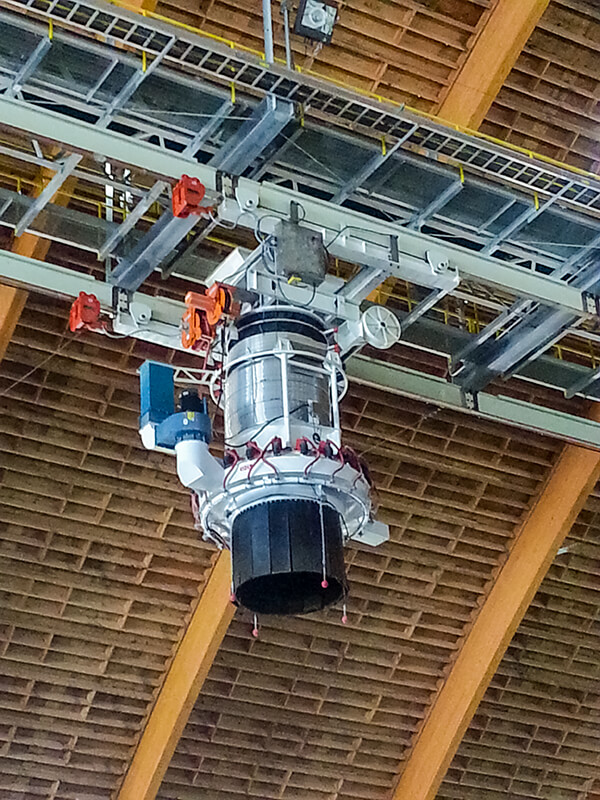

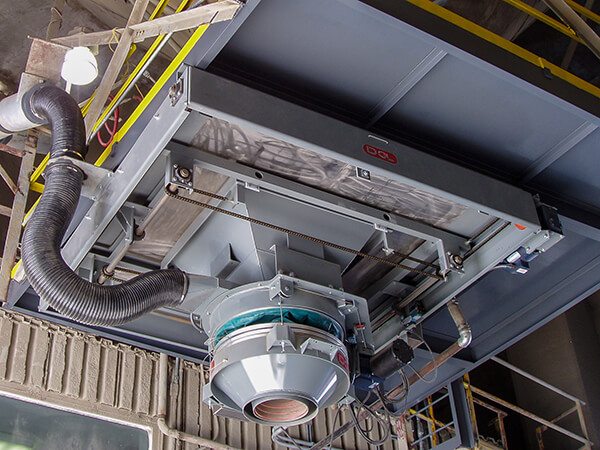

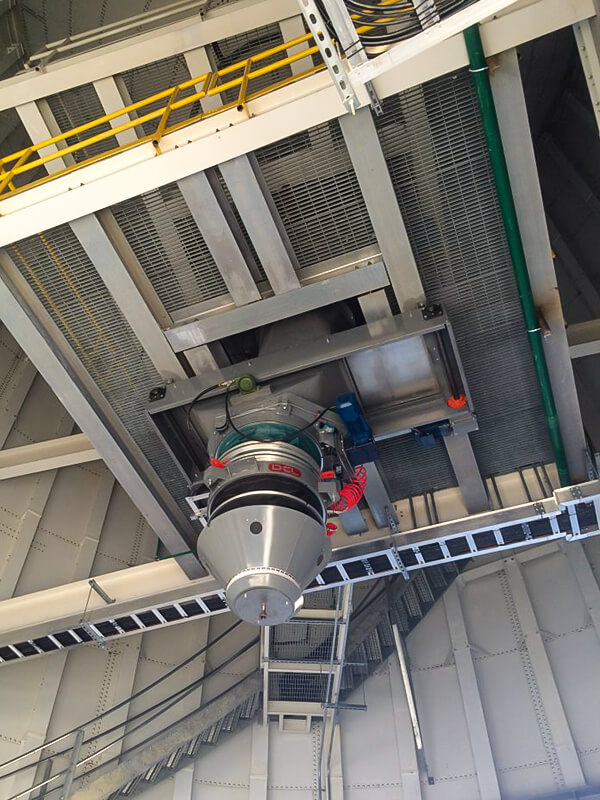

Positions standard duty loading spouts in rotary X and Y axis.

Loading area up to 12’-0” diameter.

Rotary loading spout positioners increase your speed and efficiency in any loading operation. Rotary positioners are used to move standard duty loading spouts horizontally in a radial axis when loading trucks or railcars.

Rotary positioners allow your driver to stop the vehicle in a designated loading area without having to be precise.

The loading spout can then be positioned directly above the vehicle hatch. This eliminates vehicle re-spotting once in your loading station.

DCL offers a selection of rotary positioners that provide radial horizontal travels from 4 feet [1.2 m] diameter area up to 12 feet [3.6 m] diameter area giving a total radial loading area of up to 113 square feet [10.5 m²].

A choice of construction materials allows you to effectively handle all types of products – fine, granular, lumpy, abrasive and corrosive – and difficult dusty or sanitary applications.