Diverts vertical material flow to one of two outlets at a time.

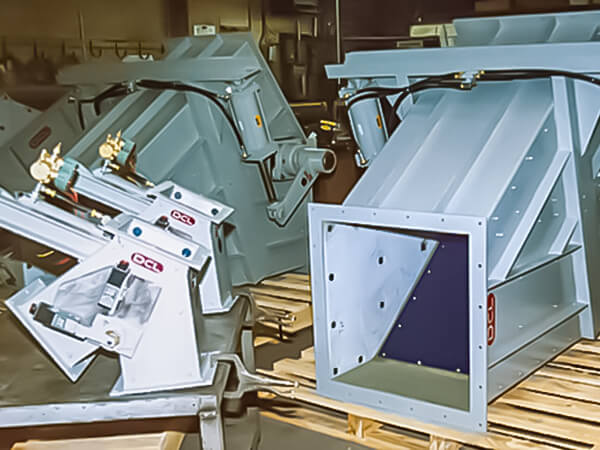

Sizes from 6” to 36” square. Offset and symmetric versions available.

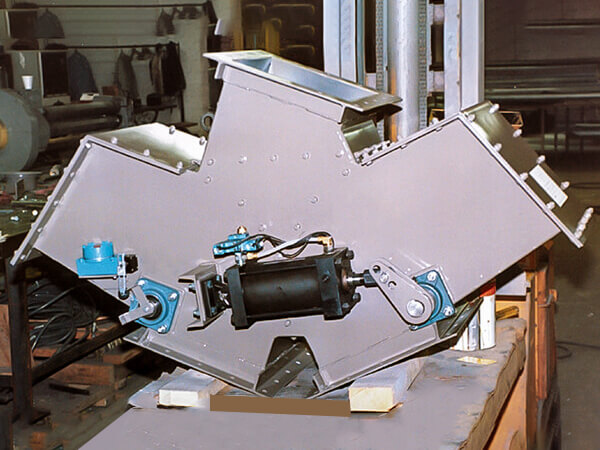

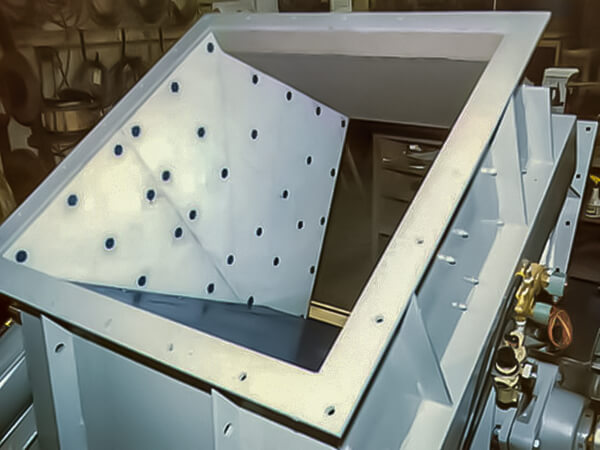

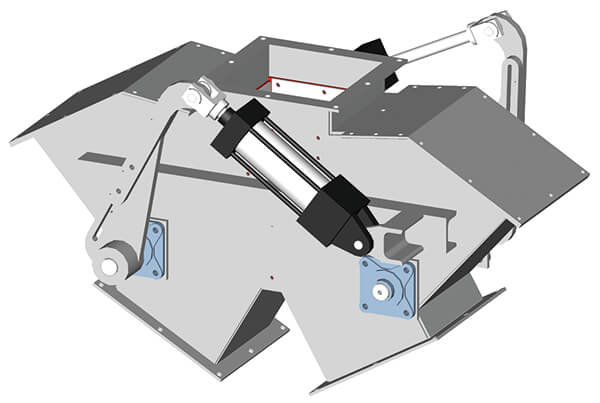

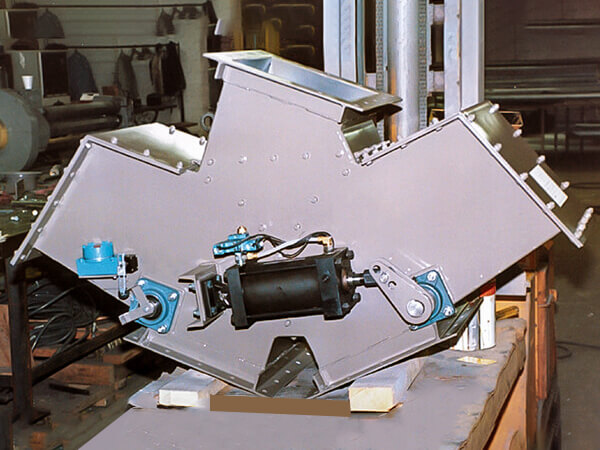

Flat blade diverter valves are designed to direct product flow from outlets of dry bulk storage bins, silos, conveyors, gravity flow chutes and other discharge points. DCL’s FBD housing is constructed of plate steel with cross member supports on larger sizes. The reinforced blade pivots on two flanged bearings, allowing it to open and close with ease.

Flat blade diverter valves can be actuated in many ways; pneumatically for fast action, hydraulically for power, electrically for convenience and manually with a chain wheel or lever. The seals on the flat blade diverter are designed to eliminate product leakage when the blade is in the diverted position. The seals are located at the top, sides and bottom of the blade. Blade seals are selected according to the material being handled and are available to suit any application.

DCL offers a large selection of flat blade diverter valves from 6 inches [152 mm] square up to 36 inches [914 mm] square. Flat blade diverter valves are also available in sizes larger than 36 inches [914 mm] and in special configurations including hardened liners.

The FBOD flat blade offset diverter valve is configured to direct the product flow straight through or to one side of the diverter. Typical product outlet offsets are 30 or 45 degrees off center. One blade and actuator is used on this diverter valve.

FBSD flat blade symmetric diverter valves have two product outlets, each 30 or 45 degrees off center. One blade and actuator is used on this diverter valve.

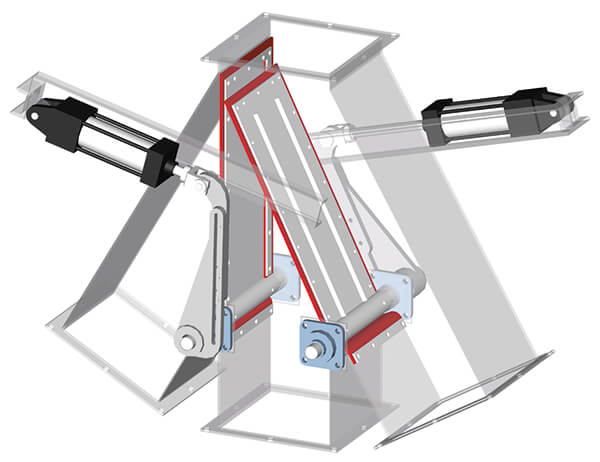

The FBTV flat blade diverter valve has one inlet and three outlets. The two side outlets are 30 or 45 degrees off the center outlet. Two blades and actuators are used on this valve.

A choice of construction materials allows you to effectively handle all types of products – fine, granular, lumpy, abrasive and corrosive – and difficult dusty or sanitary applications. You can also choose from the electrical options that are best suited for your environment: NEMA 4, NEMA 4X, NEMA 7, NEMA 9, 120V/220V control, 460V/415V power, etc.